The limestone industrial mill is an efficient and environmentally friendly ore milling equipment, which can produce 50-3000 mesh limestone powder. The limestone mills produced by CLIRIK include HGM series superfine mills, CLUM series superfine vertical mills, and YGM series Raymond mills. They can all be used to make non-metallic mineral powder, such as dolomite, carbon black, calcium carbonate, calcite, vermiculite and so on.

What is limestone and what is uses?

The main component of limestone is calcium carbonate (CaCO3) with a Mohs hardness of 3. There are quicklime and slaked lime. After being mined from limestone, limestone is crushed to form limestone particles, namely stone, sand, or further ground to form limestone powder, which is widely used in building materials, highways, metallurgy, chemical industries and other industries.

Limestone can be directly crushed into crushed stone aggregate for the production of building materials, or it can be burned into quicklime through specific equipment, and quicklime can be used in large quantities for desulfurization in power plants. Quicklime will become slaked lime after absorbing moisture or adding water. The main component of slaked lime is calcium hydroxide Ca(OH)2. It can be mixed with other materials to make limestone slurry, lime paste, etc. It is often used as a coating material and tile adhesive. mixture. At the same time, limestone is also an important raw material for many industrial production.

Limestone crushing and grinding process:

1. Coarse:

Large pieces of limestone materials are uniformly fed to the jaw crusher by the vibrating feeder through the silo for coarse crushing. After the coarsely crushed materials are screened by the vibrating screen, they are transported to the impact crusher by a belt conveyor.

2. Medium and finely divided:

After the materials to be processed transported to the impact crusher are crushed by the impact crusher, the circular vibrating screen is used to screen the crushed materials after the impact crusher, and the larger particle materials are returned to the impact crusher and crushed again. If finer products or shaping are required, the crushed materials are sent to the sand making machine for further crushing and shaping.

3. Grinding:

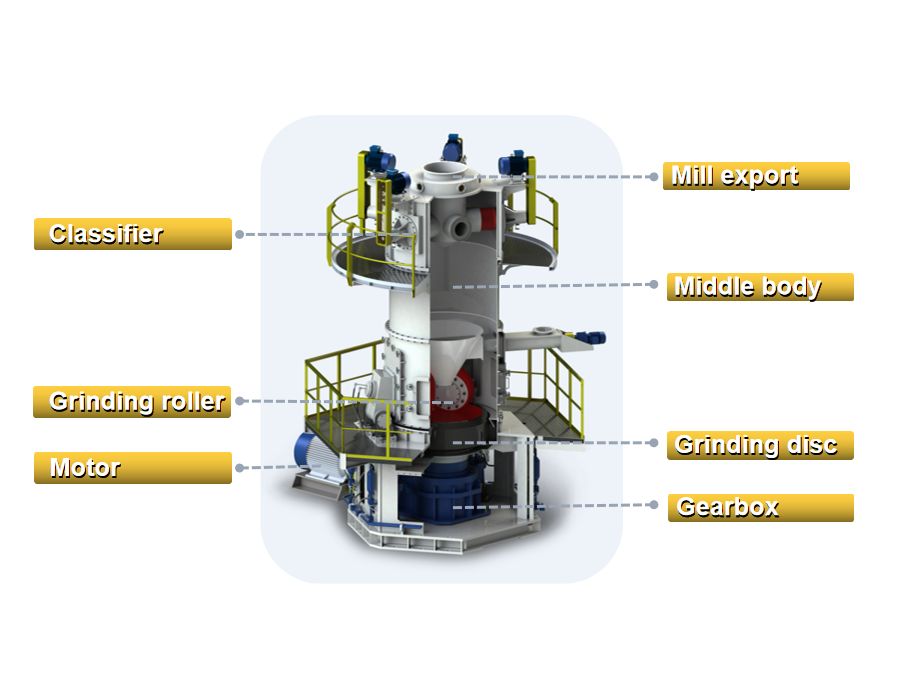

The crushed small pieces of limestone are sent to the silo by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the vibrating feeder for grinding.

4. Select powder:

The ground material is classified by the classifier along with the system airflow, and the unqualified powder is classified by the classifier and then returned to the main machine's grinding cavity for re-grinding.

5. Collection powder:

The powder that meets the fineness enters the powder collection system through the pipeline with the air flow, and the gas and powder are separated. The finished powder is sent to the finished product silo by the conveying device, and then is packaged by a powder tanker or an automatic baler.

Recommendations for Limestone Industrial grinding mills:

Limestone is a relatively common ore, and its uses are very wide. After the limestone is processed and produced, limestone powder can be obtained. Limestone powder with different finenesses has different application fields. Common limestone powder has 200 mesh, 400 mesh, 800 mesh, 1200 mesh, 1500 mesh and above. Several limestone mills are recommended below:

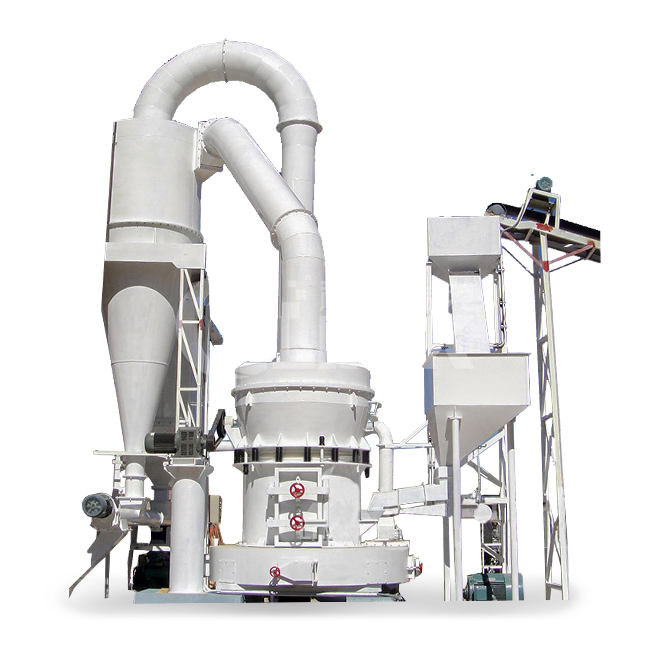

HGM Ultrafine Grinding Mill >>

The equipment can grind non-metallic ores with Mohs hardness less than 6, and the fineness of the finished powder is 150-3000 mesh, which can be adjusted freely. The ultrafine mill has a small footprint, high efficiency, low energy consumption, energy saving and environmental protection, simple operation and convenient maintenance, and is very popular at home and abroad.

The equipment can grind non-metallic ores with a hardness of less than 7 in the mode, and the fineness of the finished powder is 150-3000 mesh, which can be adjusted freely. Its output is higher than HGM, the fine powder content in the finished powder is higher, and the powder shape is better. The ultra-fine powder it produces is more suitable for high-end fillers, such as papermaking and advanced coatings.

The equipment is improved and upgraded on the basis of the traditional Raymond mill. Compared with the traditional Raymond mill, it is more efficient, more environmentally friendly, and has a lower investment. It is more suitable for the production project of the production of powder below 500 mesh in the initial stage of business.