Products

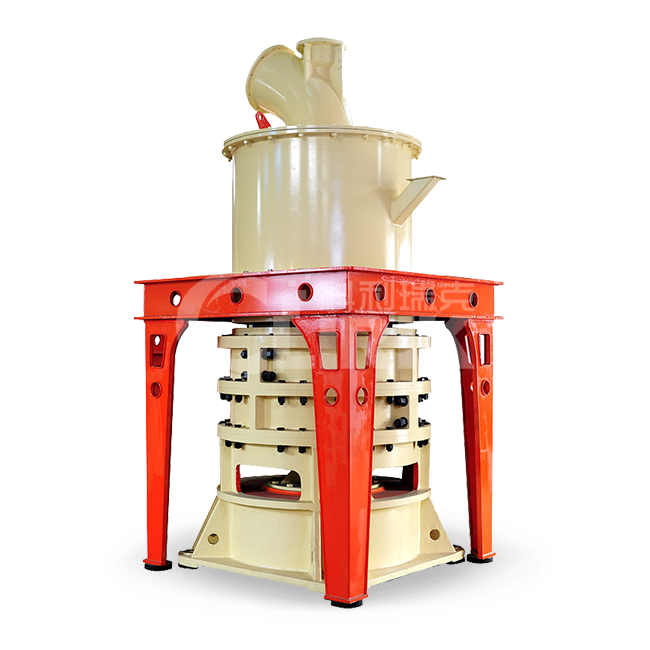

YGM Raymond Grinding Mill

Feed size.: <20 mm

Output: 1-30 T/H

Raymond mill is also called high-efficiency Raymond grinding mill and high-pressure rotary roller mill. It is suitable for the preparation of various mineral powders and coal powders, such as the fine powder processing of raw material ore, gypsum ore, coal, and other materials.

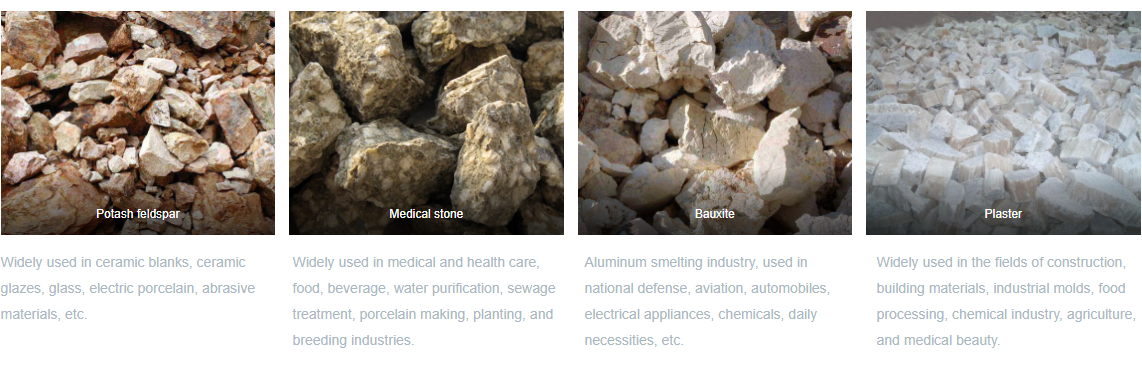

It is suitable for processing various non-flammable and explosive minerals with Mohs hardness below 9.3 and humidity below 6%. Such as gypsum, talc, calcite, limestone, marble, potash feldspar, barite, dolomite, granite, kaolin, bentonite, medical stone, bauxite, red iron oxide, iron ore, etc.

The fineness of the finished product is between 80-600 mesh. Through the joint action of the analyzer and the fan, it can meet the requirements of different users.

Brief Introduction Of Raymond Grinding Mill

Discharge fineness: 80-600 mesh

Applications Of Raymond Grinding Mill

Raymond grinding mills are commonly used grinding equipment, which is widely used in the grinding and processing of mineral materials in the fields of metallurgy, building materials, chemicals, mining, and other fields.

2 The fineness of the finished powder is uniform, and the sieving rate is 99%, which is difficult for other milling equipment to have.

3 The transmission device of the main machine of the pulverizer adopts a closed gear box and belt wheel, with stable transmission and reliable operation.

4 The important parts of Raymond grinding Mill are made of high-quality steel, and the wear parts are all made of high-performance wear-resistant materials. The whole machine has high wear resistance and reliable operation.

5 The electrical system adopts centralized control, the grinding workshop can basically realize unmanned operation, and the maintenance is convenient.

The ground powder is blown away by the airflow and separated by a classifier. The powder conforming to the fineness enters the cyclone collector through the pipe with the airflow and is separated and collected. Finally, the powder in the tube is discharged into finished powder.

The large cyclone collector is arranged at the upper end of the suction fan of the return duct, and the airflow of the whole system is a closed-loop, which flows and circulates under the state of positive and negative pressure.

Features Of Raymond Grinding Mill

1 The three-dimensional structure of the Raymond grinding mill has a small footprint and is strong in complete sets. From the block material to the finished powder, it forms an independent production system.

Working Principle Of Raymond Grinding Mill

The raw material is crushed to less than 20 mm by the jaw crusher and then lifted to the storage hopper by the elevator. Then through the feeder, the raw materials are uniformly, quantitatively, and continuously sent to the main machine for grinding.

2 The fineness can be adjusted between 80-600 mesh.

3 The reducer of Raymond roller grinding mill adopts a new type of reduction device: convenient adjustment and uniform particle size.

4 Large-capacity shovel: increase the feeding progress.

5 Advanced host structure: stable operation, low noise, convenient maintenance, large grinding area.

6 The classification accuracy is high.

7 New type of grinding roller device: The grinding roller device adopts a new type of maintenance-free structure, and the sealing is reliable.

8 Large conveying capacity: high-pressure centrifugal fan.

9 Environmental protection, no dust pollution.

Advantages Of Raymond Grinding Mill

1 High production capacity, 1-30t/h.

Parameter Of Raymond Grinding Mill

|

Model |

Roller Quantity |

Roller Diameter |

Roller Height |

Ring Inner Diameter |

Ring Height |

Feeding |

Finished |

Mill System |

Capacity |

Overall |

|

YGM7815 |

3 |

260 |

150 |

780 |

150 |

15 |

0.613-0.033 |

35.7 |

1.0-3.0 |

4300*3500*5100 |

|

YGM9517 |

4 |

310 |

170 |

950 |

170 |

25 |

0.613-0.033 |

72.65 |

2.1-5.6 |

7100*5900*7900 |

|

YGM1280 |

3 |

370 |

240 |

1170 |

240 |

20 |

0.613-0.033 |

145.15 |

4.5-12.0 |

9300*5600*8200 |

|

YGM1300 |

4 |

410 |

280 |

1270 |

280 |

20 |

0.613-0.033 |

202.15 |

6.5-16.0 |

9100*8200*8400 |

|

YGM1620 |

4 |

450 |

300 |

1500 |

300 |

20 |

0.613-0.033 |

322.2 |

8.0-20.0 |

12500*5700*10500 |

|

YGM1720 |

4 |

510 |

300 |

1720 |

300 |

35 |

0.613-0.033 |

450 |

10.5-28.0 |

11550*9500*10500 |

OUR FACTORY:

FAQ:

1. Who are we?

Shanghai SBM Ultrafine Powder Technology Co., Ltd is specializing in research, manufacture, and sales of all kinds of grinding mills. We have devoted into the grinding field for more than 30 years.

2. Why is Raymond grinding mill so popular in the market?

(1) After the improvement of the Raymond grinding mill, the fineness of the finished material is more uniform, the pass rate is higher, and the grinding time is shortened.

(2) Raymond roller grinding mill runs more stable.

(3) Raymond roller mill has higher production efficiency.

(4) Raymond roller mill has a lower failure rate.

(5) Raymond mills are more environmentally friendly.

3. Why should you buy Raymond roller grinding mills from us?

CE, ISO9001

Factory sell directly

30 years experience, professional

Sales market all over the world

4. What payments can we accept?

Accepted delivery terms: FOB, CFR, CIF, EXW, CPT, DDU, express;

Acceptable payment currency: USD;

Acceptable payment methods: T/T, L/C, Western Union;

Company strength

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

So far, we have established a whole production chain, the products covermicro powder grinding mill, high pressure grinding mill, European version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on. Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.

We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front. Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment,optimized process configuration and a full range of technical support, therefore we always follow your steps, pursue your value and achieve your benefit.