Products

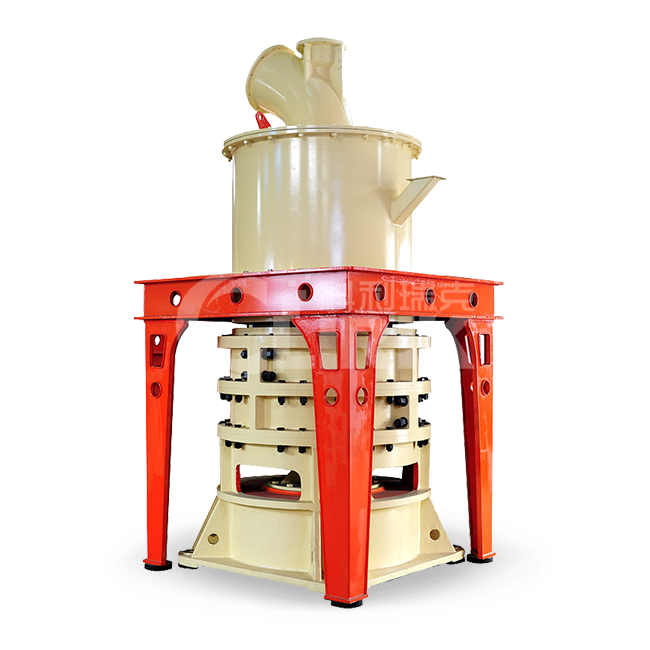

LXMC Ultra Fine Wet Stirring Mill

LXMC ultra fine wet stirring mill is widely used in grinding calcium carbonate, soft or hard kaolin, coal-water slurry, mica, barite, illite, gypsum, rare earth, magnesium oxide, aluminum oxide, red iron oxide, magnetic materials, and so on. Products fineness up to micron grade and sub-micron grade.

Widely used in many industries:

Products can be directly used for paper filling, coating or after drying for coatings, paints, cosmetics, disposable diapers, plastic, PVC, and rubber filler wire and cable. Has a large output, high efficiency, low energy consumption, environmental protection and other features.

Homogenization slurry into the bottom of grinding chamber, transmission device drives multistage mixers motivation in multi dimensions and self rotation way, together with slurry and ceramic beads or zirconium beads. The mixer tank is made by high resist abrasion with odd shape. Materials are grind by weight and pressure of smooth surface balls and the stress of screw rotating centrifugal stress produced by friction, extrusion and shear, gentle rub and under the action of impact force, effectively.

Using the industrial teeth , said the mixer made of tungsten carbide alloy, reasonable linear velocity, can effectively reduce the starting torque, greatly reduce the wastage of the mill grinding meson balls, the pulp whiteness no effect;Improve equipment operation efficiency and prolong the service life. The material properties does not change.

Mill feed particle size is 200-400 mesh, largest single machine can grind 2 microns or less D90 (6000 mesh) of the following products; Optimization of the length to diameter ratio for pulp residence time is long, the material running route is long, high crushing ratio, uniform particle size distribution, particle shape is spherical.

Working Principle of wet stirring mill:

• High productivity, high grinding efficiency, low energy consumption.

• Reliable and stable mechanical properties. Vertical-shaped star wheel reducer higher transmission efficiency, run more smoothly.

• The components inside the mill with high hardness wear-resistant materials, long service life.

Features of wet stirring mill:

• Ultra fine powders, the finnest powders reach t o 2 micron with content 90% for milling one time.

Model: LXMC1000

Technical Specification:

|

Technique |

Single mill |

Two mills in Series |

|

|

Powder finness -2 micron |

D60 |

D90 |

D95 |

|

Solid content |

70%-75% |

70-75% |

70-75% |

|

Capacity per hour |

1.4-1.8 |

0.6-0.8 |

0.7-0.9 |

|

The dosage of dispersants(Kg/t) |

4 |

10 |

14 |

|

Grinding meson balls loss(Kg/t) |

0.2-0.4 |

0.5-0.6 |

0.8-1.2 |

|

Power consumption(KW/t) |

<45 |

<130 |

<170 |

Model: LXMC3600

Technical Specification:

|

Technique |

Single mill |

Two or more mills in series |

||

|

Powder finness -2 micron |

D60 |

D90 |

D95 |

D98 |

|

Solid content |

70-76% |

70-76% |

70-76% |

70-76% |

|

Capacity per hour (dry materials) |

3-3.8 |

1-1.5 |

1.8-2.2 |

1.5-1.8 |

|

The dosage of dispersants(Kg/t) |

4 |

8 |

12 |

15 |

|

Grinding meson balls loss(Kg/t) |

0.3-0.4 |

0.5-0.6 |

0.8-1.0 |

0.8-1.2 |

|

Power consumption(KW/t) |

<40 |

<125 |

<145 |

<180 |

Model: LXMC5600

Technical Specification:

|

Technique |

Single Mill |

Two or more mills in series |

|

|

Main unit quantity |

One mill |

Two mills |

Three mills |

|

Solid content |

70%-76% |

70%-76% |

70%-76% |

|

Powder finness -2 micron |

D60 |

D75 |

D98 |

|

Capacity per hour (dry materials) |

4.5-5 |

4.5-5 |

4.5-5 |

|

The dosage of dispersants(Kg/t) |

<5 |

<6 |

<15 |

|

Grinding meson balls loss(Kg/t) |

0.3-0.4 |

0.4 |

1-1.2 |

|

Power consumption(KW/t) |

<40 |

<50 |

<185 |

Company strength

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

So far, we have established a whole production chain, the products covermicro powder grinding mill, high pressure grinding mill, European version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on. Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.

We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front. Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment,optimized process configuration and a full range of technical support, therefore we always follow your steps, pursue your value and achieve your benefit.