Pyrophyllite industrial powder grinding mill machine can grind pyrophyllite into fine powder. There are many types of pyrophyllite industrial powder grinding mill machine, includes coarse powder mill, Raymond mill, ultrafine grinding mill, vertical roller grinding mill, etc.

What type of mineral is pyrophyllite?

Pyrophyllite is a kind of clay mineral with fine texture and low hardness (1-2). Pyrophyllite is generally white, gray, light blue, light yellow, light green and greenish brown. Transparent to translucent, pearly luster on fresh surface, oily feeling when touched.

Classification of pyrophyllite:

According to chemical and mineral composition, pyrophyllite can be divided into waxstone pyrophyllite, diaspore pyrophyllite, kaolinite pyrophyllite, siliceous pyrophyllite, etc.

The main mineral of pyrophyllite is pyrophyllite, which accounts for 90%. The others are chalcedony, limonite, and diaspore, which can be used to make ceramics, sculptures, fillers, coatings and refractory materials.

The main mineral of diaspore-based pyrophyllite is pyrophyllite, and the secondary mineral is diaspore, which contains trace amounts of limonite, rutile, etc., which can be used to make refractory materials and glass crucibles.

Kaolinite pyrophyllite is the main mineral kaolin, and the secondary mineral is pyrophyllite, which contains trace amounts of limonite, rutile, etc., which can be used to make ceramics and refractory materials.

The main mineral of siliceous pyrophyllite is pyrophyllite, the minor minerals are quartz, chalcedony, and the trace minerals are limonite, etc., which can be used to make ceramics, refractory materials, fillers, etc.

What is pyrophyllite used for?

Pyrophyllite is widely used as an admixture for refractory materials, ceramics, building materials, glass fibers, pesticides, molecular sieves, and rubber due to its insulation, acid resistance, low thermal conductivity, high melting point and high specific heat. , Paper, paint, plastics, candy, medicine, etc., in addition to synthetic diamond, petroleum, electrical, etc. also have applications; it can also be used as high-grade paving stone.

Pyrophyllite grinding process

1. Crushing stage: Large pieces of material are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Grinding stage: Small pieces of material that meet the conditions for entering the mill are uniformly and quantitatively fed into the grinding chamber of the mill through the conveying and feeding system, and pulverized in the grinding cavity.

3. Classification stage: the ground material will be classified by the classifier along with the airflow of the system, and the unqualified powder will be classified by the classifier and returned to the main machine grinding cavity for re-grinding.

4. Powder collection stage: The powder that meets the fineness enters the powder collection system with the airflow through the pipeline, and the gas and powder are separated. The finished powder is sent to the finished product silo by the conveying device, and then is packaged by a powder tanker or an automatic baler.

Coarse flour process:

1. Crushing stage: Large pieces of material are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Pulverizing stage: the small pieces of material that meet the conditions of entering the mill are uniformly and quantitatively fed into the mill by the conveying and feeding system, and can be formed at one time.

Core equipment recommendation

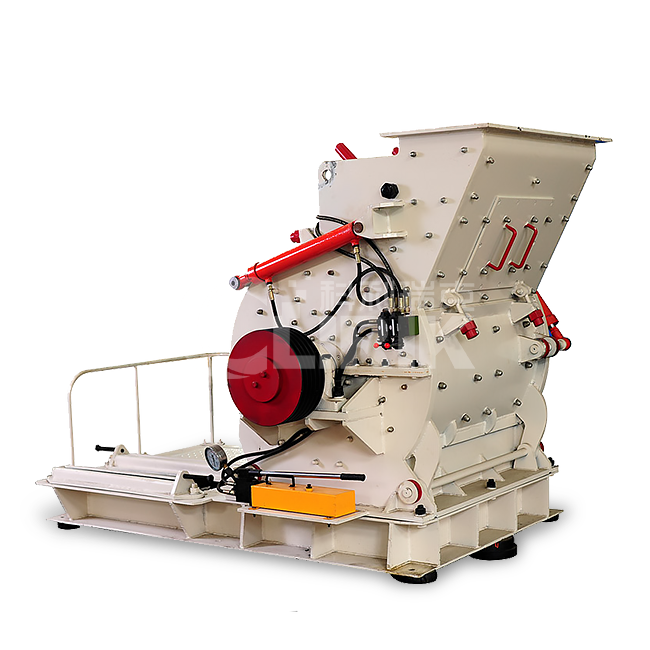

Coarse powder mill

Coarse powder mill

Final product fineness: <8mm

Capacity: 50-100t/h

• High capacity and low powder consumption

• Uiform particle size with high crushing and crushing ratio

• Simple structure

• Easy operation, low investment

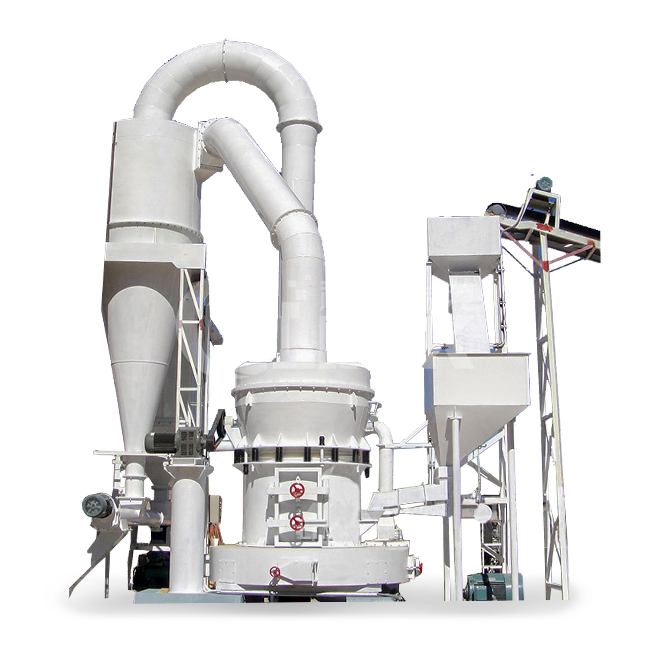

YGM Raymond mill

YGM Raymond mill

Final product fineness: 50-500mesh

Capacity: 1-30t/h

High production capacity

Advanced host structure: stable operation, low noise, convenient maintenance, large grinding area.

The classification accuracy is high.

New type of grinding roller device: The grinding roller device adopts a new type of maintenance-free structure, and the sealing is reliable.

Large conveying capacity: high-pressure centrifugal fan.

Environmental protection, no dust pollution.

HGM ultrafine grinding mill

HGM ultrafine grinding mill

Final product fineness: 200-2500mesh

Capacity: 0.2-45t/h

High efficiency

Long life cycle of spare parts

High safety and reliability, High fineness and flexible adjustment

Environment-friendly

CLUM vertical roller grinding mill

CLUM vertical roller grinding mill

Final product fineness: 325-3000mesh

Capacity: 0.2-45t/h

• The finished product has low power consumption, High grinding efficiency, High production capacity

• Advanced control system, saving labor force

• Use special wearable alloy materials, long service life of mill

• No clang and slight vibration when the mill is working, fully sealed and environmentally friendly

Get More

Pyrophyllite grinding powder application & technical indicators

Ceramics, paper making, rubber products, cosmetics, pesticides, etc.

Production fineness: about 200 mesh

It is used as a filler and carrier in ceramics, papermaking, rubber products, cosmetics, pesticides and other fields; the new use of pyrophyllite is to make paint, and it is also a good raw material for making siding, and it can also be used to make white cement.

Refractory materials, refractory bricks

Production fineness: 3mm

Pyrophyllite can be used in the application of refractory materials and refractory bricks.