What is perlite?

Perlite is a kind of volcanic eruption acid lava, vitreous rock formed by rapid cooling. It is a white granular material with a honeycomb structure. Perlite mines include perlite, obsidian and turpentine. The principle of perlite is that the perlite ore is crushed to form ore sand of a certain size, after preheating roasting, rapid heating, the water in the ore is vaporized, and it expands inside the softened vitreous ore to form a porous structure with a volume expansion of 10-30 times Of non-metallic mineral products.

Characteristics of perlite

Perlite is brittle, expands when exposed to heat, but does not shrink when exposed to cold. It has pearl luster and grease luster, has special arc-shaped cracks, and is fire-resistant.

Use of perlite

Perlite can be made into perlite products, which have the properties of lightweight, low thermal conductivity, strong sound absorption, non-corrosion, non-burning, acid-base, non-toxic and tasteless. It is a high-efficiency and ultra-lightweight heat preservation, heat insulation, sound insulation, and decoration material.

1. Construction field

Closed-cell perlite is a key material for the manufacture of moisturizing mortar, which is widely used for moisturizing the interior and exterior walls of housing construction. Due to the characteristics of perlite, it can be used for concrete aggregates; lightweight, thermal insulation, and sound-absorbing panels; fire-resistant roofs, and lightweight anti-freezing, earthquake-proof, fire-proof, radiation-proof, and other high-rise building engineering wall fillers, mortar, and other building materials.

2. Chemical industry

Used in filter aids and fillers. The processed products can be used to make molecular sieves, filters, detergents; to filter fine particles, algae, bacteria, etc.; to purify various liquids; chemical industry Plastics, paint spray industry detoxification, purification of waste oil, petroleum dewaxing, fractionated alkanes, hydrocarbons; as a filler in pigment enamel, glaze, plastic, resin and rubber industries; catalysts in chemical reactions, and oil well grouting mixtures.

3. Horticulture

Perlite can transform the soil, regulate soil compaction, prevent crops from lodging, control fertilizer efficiency and fertility, and act as a diluent and carrier for pesticides and herbicides.

4. In the beverage, beer, and pharmaceutical industries, closed-cell perlite can be used as filter ceramics, filter aids, etc.

5. In the chemical industry and furnace manufacturing industry, closed-cell perlite can be used as heat pipe moisturizing, furnace insulation products, and moisturizing products.

6. In the military industry, closed-cell perlite can replace expensive glass beads in floatation.

7. In the fire-fighting industry, closed-cell perlite can be used to manufacture various fire-fighting appliances.

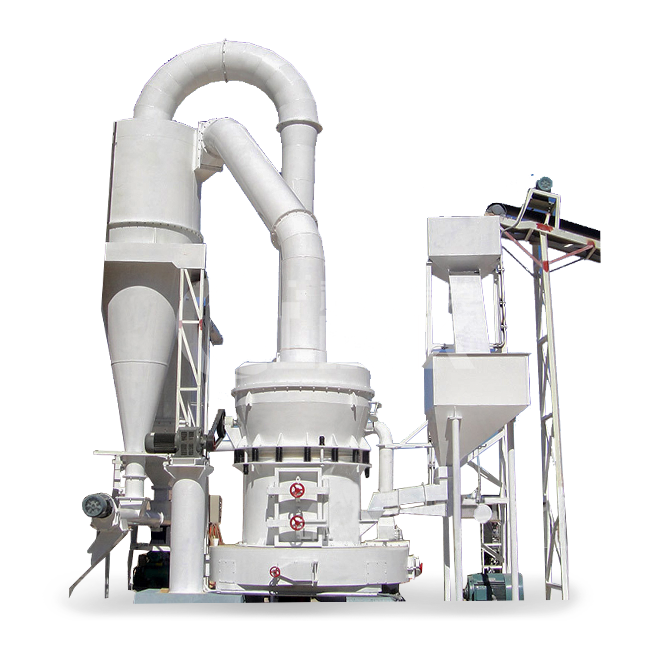

Application of perlite ore processing equipment Raymond mill

CLIRIK perlite mill has obvious advantages, performance characteristics, scientific and reasonable structure, and is widely used in the field of perlite grinding processing by virtue of advanced powder making technology. CLIRIK's high-pressure suspension roller Raymond mill is a common equipment for perlite processing. The fineness of the finished product can be adjusted between 80-600 mesh. The output is 30%-40% higher than that of the traditional mill, and the energy consumption is greatly reduced. Ideal equipment for perlite grinding and processing.

Raymond vertical roller mill

Number of grinding rollers: 3-5

Feeding size: 30 mm

Output of finished products: 1-25 t/h

Product fineness: 0.022-0.18 mm

Application range: This mill can be widely used in metallurgy, chemical rubber, coatings, plastics, pigments, inks, building materials, medicine, food, and other processing fields. It has a remarkable grinding effect and leading domestic technology. It is ideal equipment for non-metallic mineral processing.

Application materials: High-yield and efficient processing of non-metallic minerals such as bauxite, titanium dioxide, ilmenite, phosphate rock, clay, graphite, calcium carbonate, barite, calcite, gypsum, dolomite, potash feldspar, etc. The fineness adjustment is convenient and the operation is simple.

Grinding characteristics: The mill effectively increases the unit output of a single device and reduces the energy consumption per unit output. It has the technical advantages of wide use, simple operation, convenient maintenance, stable performance, high efficiency, environmental protection, and high-cost performance. It has a broad market prospect.