Limestone is a carbonate rock with calcite as the main component. Sometimes it contains dolomite, clay minerals and detrital minerals, with gray, gray-white, gray-black, yellow, light red, maroon and other colors, the hardness is generally not large, and it reacts violently with dilute hydrochloric acid.

Limestone has low hardness and average compressive strength, and is widely used in many fields such as construction, metallurgy, and chemical industry. Limestone is brittle. Therefore, in the design of the crushing process, the crushing equipment based on the principles of grinding, beating and impact is excluded, and the crushing equipment based on the lamination principle is selected as much as possible to control the stone powder content of the stone and achieve the greatest economic benefits. Typical crushing equipment configuration is jaw crusher, cone crusher, vibrating screen and other process configurations.

The limestone crushing production line adopts two-stage crushing, which fully considers the matching of technical parameters between different levels of crushing, which can not only ensure the grain quality of the product to the greatest extent, but also meet the requirements of crushing ratios of various types of crushers. The finished stone fully meets the requirements of ordinary building stone. At the same time, auxiliary dust removal equipment can be configured according to customer requirements.

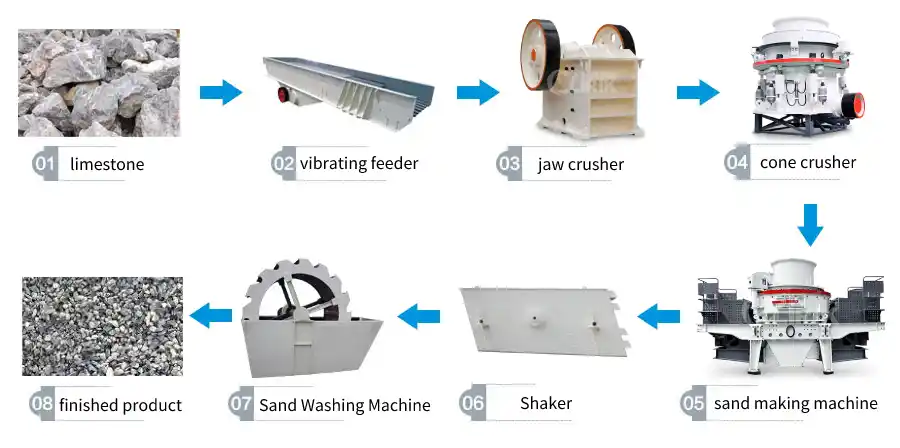

Process flow of limestone crushed stone production line

1. The limestone first enters the jaw crusher for preliminary crushing, and the outgoing stone is sent to the cone crusher to be crushed again through the vibrating feeder.

2. A small adjustment silo is built at the feed of the cone crusher to feed the cone crusher evenly and full cavity, so as to produce qualified finished products with better grain shape.

3. After the cone crusher is crushed, the material is classified and screened by the circular vibrating screen. The material in the upper layer larger than the finished product is returned to the cone crusher for re-crushing, and the material in the lower layer enters the sand making machine for shaping. The materials are classified and screened by the next-level circular vibrating screen, the materials on the upper screen surface are returned to the sand making machine to make sand again, and the lower layers are screened into the required grades of finished materials.

Limestone crushing production line equipment

>> Jaw crusher

The function of the jaw crusher is the preliminary crushing of limestone materials, which is referred to as the rough crushing link. The movable and fixed jaw plates of the jaw crusher have large kinetic energy, and the jaw crusher also has the function of screening to screen out the impurities existing between the limestones, so as not to increase the production intensity. The jaw crusher can fully crush the limestone in the crushing chamber without over-crushing, and prepare for the subsequent processing.

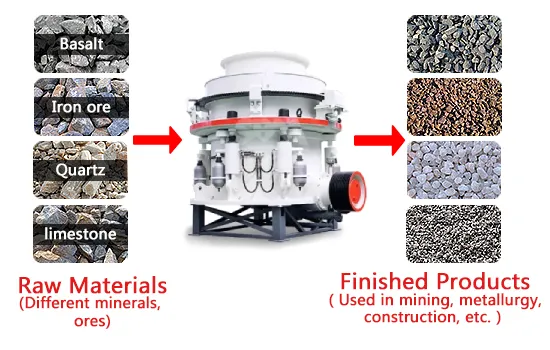

>> Cone crusher

The cone crusher adopts the unique crushing cavity type and the principle of lamination crushing. The limestone processed by it has more uniform grain size and good grain shape, which is more popular in the market.

The cone crusher has three cavity types to meet the needs of different users. It can not only coarsely crush limestone, but also crush it in medium and fine. It has the characteristics of large production volume, high crushing efficiency and low energy consumption.

The cone crusher is more environmentally friendly and has a unique cavity shape, so that the dust generated during the limestone crushing process cannot be spilled into the outside air, and it also has a certain inhibitory effect on noise.

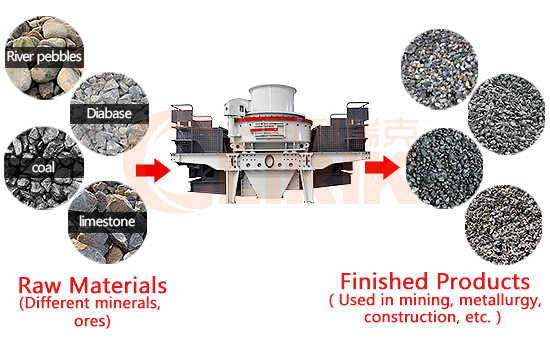

>> Sand making machine

The impact sand making machine has a high degree of automation, low operating cost, high crushing rate, energy saving, large output, less pollution and easy maintenance.

Advantages of limestone crushing production line

1. Easy to maintain and operate. Since the performance of the production line equipment itself is quite reliable, the frequency and cost of equipment maintenance can be reduced.

2. The stone crushing production line has a wide range of uses, and can be used for the crushing and processing of limestone and pebbles, thereby providing a large number of raw materials for metallurgy, building materials and other industries.

3. The stone crushing production line has excellent energy-saving effect. Compared with traditional sand making machines, the same electric power can produce more sand, and maintenance is also convenient.

4. The construction sand produced can meet the needs of modern construction, with uniform sand quality and high compressive strength, which can replace natural sand.

5. The stone crushing production line can carry out fully automatic operation process, which can effectively improve production efficiency and save industrial production costs.

6. The limestone crushing production line adopts three-stage crushing, fully considering the matching of technical parameters between crushers at all levels. It can not only ensure the grain quality of the product to the greatest extent, but also handle the requirements of various types of crushers for the crushing ratio.

7. The limestone crushing production line is economical, practical, energy-saving and environmentally friendly. The sand has good particle shape and reasonable gradation. It belongs to medium sand. All indicators meet the national standards and are high-quality concrete aggregates.