Ultrafine mills are more common in the limestone milling industry. In terms of milling, the superfine mill has superior performance. Limestone ultrafine mill is a device that integrates crushing and grinding. It abandons the limitations of traditional mills. Traditional mills can only be used for milling, not for crushing, but the current ultra-fine mills The fine pulverizer can be used for grinding and crushing operations, achieving two goals with one stone.

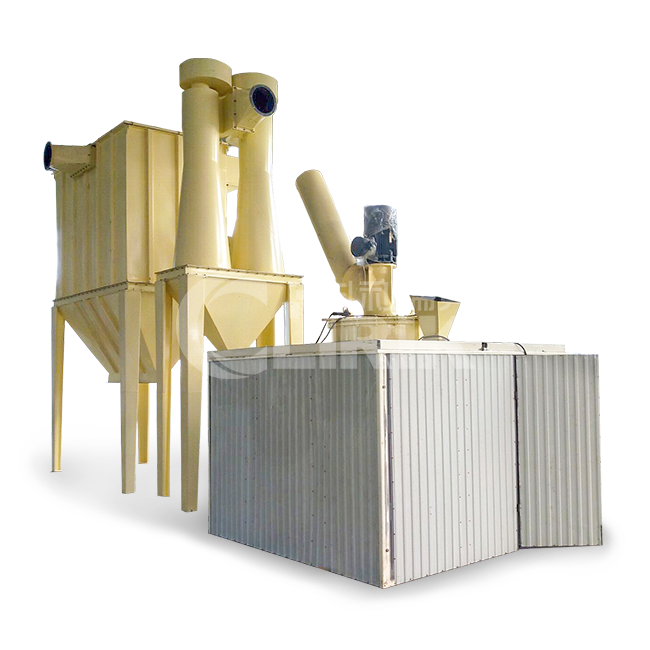

The limestone ultrafine mill features a small footprint and a strong complete set. It can form a production system from block to powder to finished powder and packaging. The uniformity of the fineness of the finished powder milled by the mill can reach 97% of the required fineness, which means that it can reach 97% through the sieve. This is incapable of other milling equipment.

In addition, the main transmission device of the mill adopts a closed gear box, which is stable in transmission and reliable in operation. The important parts of the mill are made of high-quality steel, so the whole machine is durable and reliable. At the same time, the electrical system of this series of mills adopts centralized control, and the selection is advanced and reasonable with a high degree of automation. According to customer needs, PLC or DCS automatic control system can be selected for electric control equipment to realize unmanned, modern automation and remote control.

Limestone grinding mill can be divided into: building materials, chemical industry, abrasive tools, food, casting, etc. according to its production purposes. The process flow is divided into two sections.

One is the main flow of crushing operation: limestone raw ore -> vibrating feeder -> Jaw crusher -> bucket elevator -> raw material warehouse -> impact crusher -> bucket elevator -> impact crusher (cone crusher).

One stage is the limestone grinding process, the main processes are: ultrafine mill -> bucket elevator -> conveyor -> clinker bin cooling -> storage -> finished product. Among them, the grinding process is particularly critical.

In the mining industry, people are more concerned about pollution. The problem of dust pollution has been solved very well on the body of ultra fine grinding powder. Its internal pulse processor can solve this problem. It meets the national green environmental protection machinery standard because its vibration frequency is relatively small. So there is not much noise.