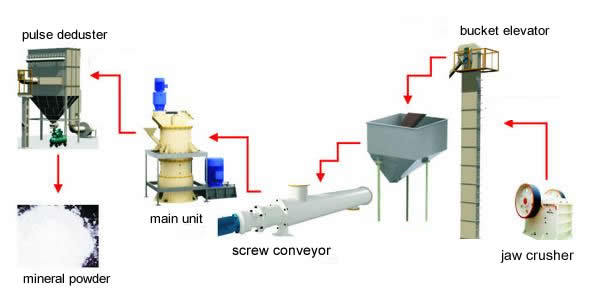

The whole ultra fine powder production working flow is, after crushed by the hammer crusher, the large materials become small size and are sent into the storage hopper by the elevator, and then evenly sent into the upper distribution plate of the turn plate by vibrating feeder and sloping feeding pipe.

The high-pressure air blower constantly inhales air within the grinding mill and, in turn, the airflow with crushed materials are brought to the classifier whose high-speed impeller will screen the airflow: the unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector. Most of the qualified powders will fall and exit from the discharging valve at the bottom; a small proportion of the fine powders, with airflow, moves to the dust cleaner, and clings to the surface of the filter bags.

At the same time, the fine powders clinging to the surface fall down by the sudden vibration of the filter bags, which is caused by the instantly ejected high-pressure gas controlled by the pulse valve. The materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed. In addition, filtered clean air will be emitted from the air outlet of muffler in the end.

Above all are the working flow of our HGM series ultra fine powder grinding mill, there are mainly five models of ultra fine mills in our company, if you are interested in this machine, or you want to know more details, welcome to leave your message on our website, and we will contact you as soon as possible. Thanks for your reading.