The cleaning treatment of industrial exhaust gas mainly involves gypsum flue gas desulfurization. Among them, the quality of the desulfurizer will determine the desulfurization effect, and limestone fine powder as the key component of the additive is the core of the entire process.

In order to ensure production capacity and additive quality, customers have very high requirements on timely output, fineness adjustable range, finished product grain stability, and production cycle. After multiple inspections, it was determined that Clirik met the needs in all aspects, which ultimately led to cooperation between the two parties.

The four production lines of this project adopt high-standard modular design in the industry, and the project investment exceeds 100 million yuan. Based on the customer's production conditions of 2 mines and 5 vertical kilns, a large-capacity heavy calcium-based ultrafine powder grinding production line with an annual output of 450,000 tons was designed.

The project is supported by the high production capacity of four sets of HGM series 125 ultra-fine grinding production lines of Collyric. With its considerable output and stable high quality, it has quickly become a local heavy calcium-based flour milling model line, filling the gap of high-quality heavy calcium powder in Fuxin City. A blank in the production of base ultrafine powder.

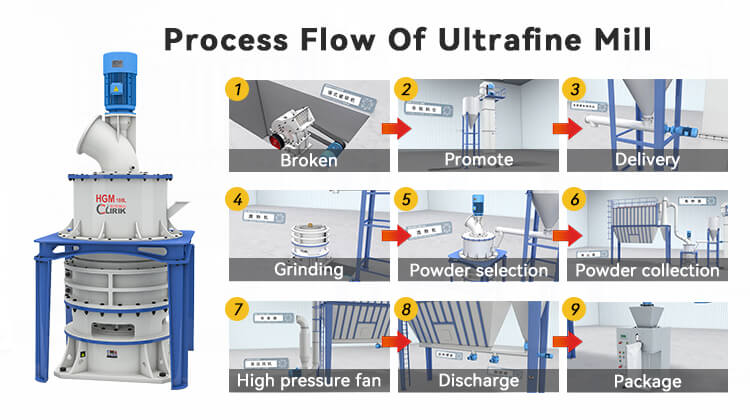

The production line was put into operation smoothly, the site layout was reasonable, the equipment ran smoothly, and was well received by customers. The overall project adopts dry roller grinding technology, designs a negative pressure production structure, and integrates crushing, grinding, screening, collection, finished product storage and other links to achieve emission standards.

For many years, Collyric has provided strong guarantee to customers around the world with its excellent equipment quality and reliable service. In the future, we will insist on output: excellent production line technology and all-round technical support, integrating "equipment manufacturers + design institutes + engineering construction teams + services", actively responding to various needs at all times, and striving to achieve "value mutual benefit and value sharing".