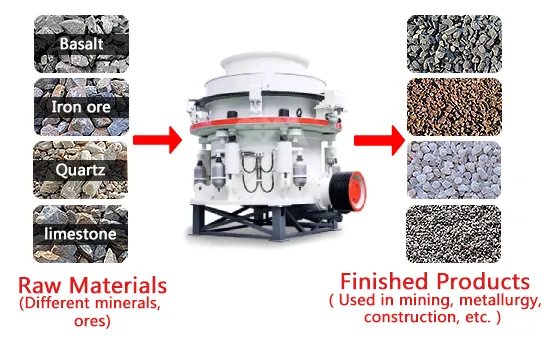

Cone crushers are suitable for crushing raw materials in metallurgy, construction, road construction, chemical and silicate industries. Widely used in mining, smelting, building materials, highways, railways, water conservancy and chemical industries and many other sectors. The cone crusher has large crushing ratio, high efficiency, low energy consumption, and uniform product particle size. It is suitable for medium and fine crushing of various ores and rocks.

The outstanding advantages of cone crusher are high production efficiency, low energy consumption in the production process, and can be applied to the crushing of medium and high strength materials. Most of the crushed materials are needle-shaped and basically medium-sized.

High-capacity, high-efficiency equipment is what every user pursues, but in addition to the equipment itself, operations in production are also closely related to its efficiency. Taking cone crusher as an example, the following production suggestions can improve efficiency to a certain extent and obtain large production capacity.

1. Adjust the size of the closed side discharge port to change the output

The output of the equipment can be achieved by adjusting the size of the closed side discharge opening.

When the size of the closed side discharge port is larger, the output of the cone crusher is higher, and the quality of the finished product is worse. On the contrary, the smaller the size of the closed side discharge port, the smaller the output and the better the quality of the finished product. Therefore, manufacturers can adjust according to their actual needs.

2. The belt conveyor evenly feeds the material

When feeding the material, the belt conveyor is required to input the material evenly, and the material must meet the requirements of the cone crusher to crush the material. Too much or too little feeding will affect the production efficiency of the equipment.

In addition, the operator needs to pay close attention to the discharge condition of the cone crusher discharge port, control the speed of the belt conveyor, and ensure normal feeding and discharging.

3. It is best to fill the feed

When installing the feeding device, pay attention to the speed of the ore entering the crusher and the corresponding drop relationship. Usually, because the speed of the conveyor is constant, only the drop height of the ore can be selected. While crowding the feeding ore, it is necessary to pay attention to the fact that the feeding cannot be too much or too little, and the height of the ore pile in the feeding device should be controlled.

4. Reduce the mineral powder entering the cylinder liner and prolong the service life of the sealing ring

Every time the lining plate is replaced, check whether the dust seal of the moving cone is in good condition. Under normal circumstances, when the wear gap between the dust seal and the sliding ring is greater than 1.5mm, the dust seal should be replaced to prevent the mineral powder from entering the cylinder liner and causing damage to the main shaft and other components.

5. The lubricating oil temperature should be kept balanced

Since the lubrication and heat dissipation of the main lubricating parts of the crusher, such as the main shaft, eccentric sleeve, eccentric shaft, frame bearing, main shaft adjusting piston, sliding bearing surface, gear rotation, etc., are mainly completed by the lubrication system, it is very important to choose a suitable cooling and heat dissipation device.

6. Pay attention to the bolting of the dust-proof sealing slip ring

If the material accumulated on the beam is not cleaned in time, the bolt follower cone of the fixed slip ring will move relative to the accumulated material together with the accumulated material, causing the tail of the bolt to wear. If there is a problem with the fixed state of the slip ring, careful technical inspection must be carried out to avoid the adverse consequences caused by the slip ring falling off.