Grinding 80-400 mesh asbestos ore processing milling equipment can use Raymond mill and vertical mill. Grinding 600-2500 mesh asbestos ore pulverizers use ultra-fine vertical mills or ultra-fine ring roller mills. What type of mill to use depends on the specific fineness and output required.

Asbestos is widely used

1. Thermal insulation products: Asbestos can be used as thermal insulation products with a wide range of varieties, such as raw materials for asbestos products, thermal equipment, thermal insulation of heat transfer systems, thermal insulation materials, anti-corrosion sealing materials, labor protection products for high temperature operations, and brake belts. The products include asbestos yarn, asbestos thread, asbestos quilt, etc.; heat insulation materials, sealing gaskets and diaphragm materials for machinery and electrical industrial equipment.

2. Asbestos sealing products: including asbestos rubber sheet, oil-resistant or acid-resistant asbestos rubber sheet, asbestos latex sheet, asbestos rubber sheet gasket, etc., widely used in various machinery and equipment pipelines in petroleum, chemical, aviation, electrical, national defense and other departments Thermal insulation materials and sealing gaskets. In addition, there are wave gaskets, self-sealing gaskets, rubber asbestos gaskets, etc. used as sealing materials.

3. Asbestos friction products: including brake linings and clutch facings, mainly used as braking materials.

4. Special asbestos products: including insulating materials, materials for electrolytic cells, chemical reagents, asbestos rollers, filter materials and other materials.

Asbestos ore processing milling equipment R series Raymond mill

R series pendulum mill is mainly composed of main machine, feeder, classifier, blower, pipeline device, storage hopper, electric control system, collection system and so on.

The host of R series pendulum mill is mainly composed of base, central shaft frame, grinding ring, plum frame assembly, grinding roller assembly, central shaft, shovel holder, shovel seat assembly, cover tube and other structures. The workpiece grinding ring and grinding roller for rolling and grinding are made of wear-resistant materials and cast, and the contact surfaces with the materials are all treated with wear-resistant treatment. The power device of the system can adopt two ways of reducer transmission and double transmission. The classifier adopts a forced turbine classifier, and the conveying and feeding system can be selected according to different materials. The collection system can be a closed-circuit collection system with double cyclones plus pulse dust collector or an open-circuit system with full pulse collection. The control system can choose automatic control and remote control modes according to customer needs.

Working principle: The material is crushed into a particle size that meets the specifications by the jaw crusher, lifted to the storage hopper by the bucket elevator, and then sent to the main machine cavity by the feeder for grinding. The roller device rotates around the central axis, and the grinding roller swings horizontally outward under the action of centrifugal force, so that the grinding roller presses the grinding ring, and the grinding roller rotates around the grinding roller axis at the same time. The material raised by the rotating blade is thrown between the grinding roller and the grinding ring, and is crushed and ground by the grinding of the grinding roller. The ground powder is blown by the airflow of the blower to the classifier above the main machine for sieving.

Those whose fineness is too coarse still fall into the main machine for regrinding. Those whose fineness meets the specifications flow into the cyclone collector with the wind, and after being collected, pass through the powder outlet pipe. The discharge is the finished product (the particle size of the finished product can be as high as 0.008mm). The purified air flows into the blower through the pipe at the upper end of the cyclone. The air path is circular. Except for the positive pressure from the blower to the grinding chamber, the air flow in the other pipes is under negative pressure. Down flow, indoor sanitary conditions are better.

As the moisture contained in the material is heated and evaporated into gas during grinding, the gas leaking into the air duct from the joints of the flanges in the pipeline, the feed inlet, etc. will cause the air volume in the circulating air path to increase, and the increased air volume will pass through the blower and The remaining pipe between the main machines leads to a simple collector, and the powder brought in by the air flow is collected and discharged from the ash collecting hopper.

Asbestos ore processing and grinding equipment--YGM series vertical pendulum grinding machine

The output of the pendulum mill is 30-40% higher than that of the traditional Raymond mill

The HC vertical pendulum mill is a technical update based on the R-type mill. The technical indicators of this product have been greatly improved compared with the R-type mill. It is a new type of mill with high efficiency and energy saving. The fineness of the finished product can be adjusted arbitrarily between 22-180μm (80-600 mesh). This product is an updated product of the R-type mill.

Asbestos ore processing and grinding equipment--vertical mill

CLUM series vertical mill is an advanced energy-saving grinding equipment integrating drying, grinding, grading and conveying.

CLUM vertical mill has the advantages of high grinding efficiency, low power consumption, large feeding particle size, easy adjustment of product fineness, simple equipment process, small floor space, low noise, small dust, easy operation and maintenance, and low operating costs. , less consumption of wear-resistant materials and other advantages.

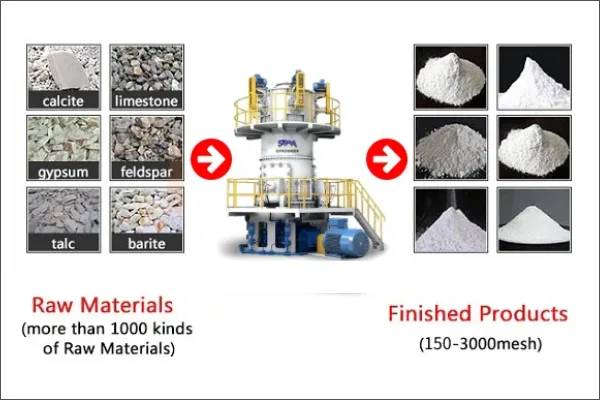

It can be widely used in electric power, metallurgy, cement, chemical industry, non-metallic minerals and other industries. It is mainly used for cement raw meal, clinker, power plant desulfurization limestone powder, slag powder, manganese ore, gypsum, coal, barite, calcite, aluminum Bauxite and other materials for grinding processing.