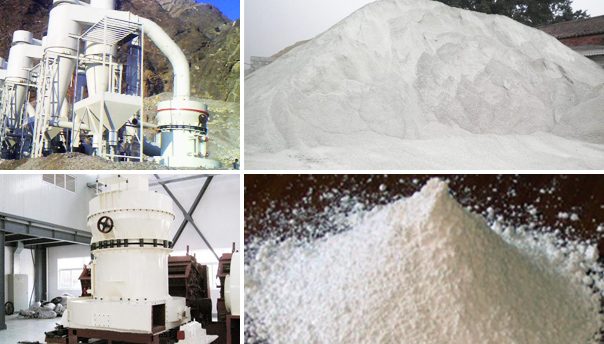

Raymond roller mill is a grinding equipment mainly used in the chemical industry, construction materials and mines.

Precautions for using Raymond roller mill in rain and snow weather

1. Because the Raymond mill is installed on the base, in rainy and rainy weather, the Raymond mill will produce greater impact and the equipment will vibrate when it is running. Moreover, when it rains, the ground is easy to loosen, causing the base to move and deviate, and it is difficult to adjust it in place. For this type of failure, it can only reduce the working time of the equipment in rain and snow, so as to avoid such failures.

2. When the Raymond mill is working in rain and snow, it is easy to enter the water inside, which may cause some parts to slip, especially the motor belt is more likely to slip. Therefore, the operator should always pay attention to the following facts: If the deviation of the belt conveyor is serious, appropriate adjustments should be made in time. The use of rubberized drive rollers can reduce the occurrence of slipping problems. Such weathered abrasives are also prone to carry impurities, such as dirt, which will cause some wear of the mill accessories, which will shorten the service life of the equipment.

How to deal with the problem of high temperature of Raymond roller mill

Raymond mill is a very common milling equipment in the milling industry. If the machine temperature is too high during use, how to deal with it?

1. Check whether the extension pipe is unobstructed, and whether the viscosity and grade of the oil meet the requirements.

2. The powder inlet bearing of the grinding roller device should be refueled in time according to regulations, cleaned regularly, and the oil seal should be replaced.

3. The bearings of the grinding roller and grinding ring should be oiled regularly.

4. The bearing room temperature should not exceed 70℃. If the bearing temperature is too high, immediately remove and clean the bearing and bearing room and other accessories, which need to be cleaned once.

5. Fan heating may be caused by high wind pressure. Sometimes we will unconsciously encounter the fan equipment during production, and the change of fan air pressure will cause the motor to heat up, so we must not change the equipment at will during production.

6. There is also the reason for the equipment itself, such as the quality is not good enough, so we should try our best to choose big-brand, high-quality equipment.

Causes and solutions of bearing heating of Raymond roller mill

The main support accessory for the operation of the pulverizer is the bearing. The bearing is also the main factor affecting the performance and production efficiency of the Raymond pulverizer. What should I do if the bearing heats up during use?

1. Too much or too little lubricating oil will cause the bearing to heat up. If it is overheated, the heat generated cannot be dissipated in time due to poor heat dissipation; while too little will not completely lubricate the bearing. During operation, the bearing will heat up. When adding lubricating oil to the bearing, it is generally better that the lubricating oil occupies about 70% of the space. Too much or too little is not conducive to the heat dissipation of the bearing.

2. The height of the bearing is different, or the rotor of the motor and the rotor of the pulverizer are not concentric, which will cause the bearing's extra conforming impact, which will lead to the phenomenon of overheating of the bearing. If this phenomenon occurs, immediately adjust the position of the bearing to avoid misalignment of the position and cause eccentric wear.

3. The bearing of the pulverizer is too tightly matched with the bearing seat. If the bearing and the bearing seat are too tightly matched, it will cause increased wear. If it is too loose, it will also cause the bearing to overheat. If this problem occurs, adjust the tightness of the bearing and the bearing seat. Degree, re-cooperate.

Therefore, many problems in daily production are caused by improper maintenance. Therefore, it is recommended to carry out regular maintenance to ensure the extension of equipment life.