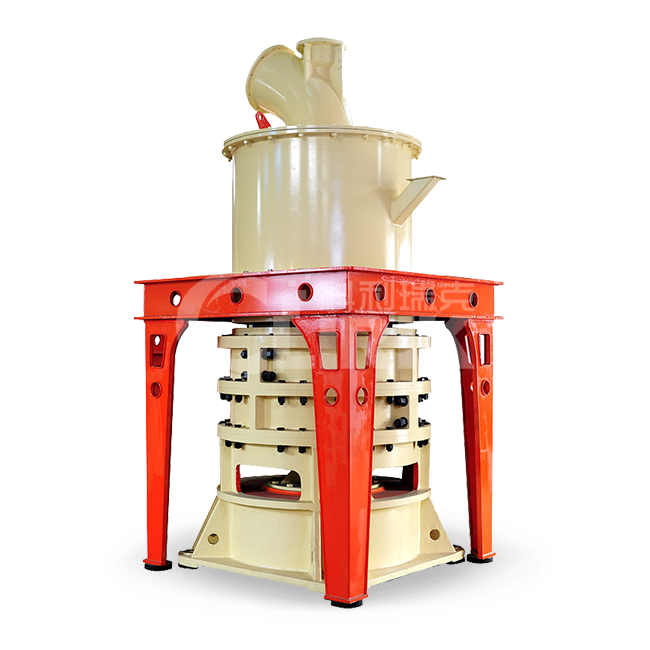

SLG Contuinuous Modifying Machine for Powder Surface

Continuous is used for dispersing powder, modifying surface and filming. The mineral powder surface modifying, widely used in the fields of non-metal stuffing or pigment like plastic rubber, adhesive, macromolecule materials, high polymer composite, functional mateirals and dope industries. It can not only improve the compatibility of both non-organic mineral stuff and organic high polymer, enhance binding force of interfaces, raise the mechanical strength and comprehensive ability, but also increase the stuffing ability of powder, save product cost and add speceial physical and chemical property to the product to some extent.

Application: SLG series ultra fine grinding machine is the machine applicable to modifying various materials. It can reach excellent surface modifications for such materials as:

1. Continuous operation, large capacity, suitable for industrialization production in various scales.

2. High use and less consumption of modifying agent, high covering and active index of powder, energy saving.

3. Both modifying and dispersion function, suitable for any fine material, special active effect for material with small proportion and big cubage weight like white carbon, mica powder and talcum powder.

4. Powder and agent mixing and running in high speed and vortex,high modifying efficiency, with little change of granulate shape.

5. Running at vacuum, air tight, no dust leakage, no pollution, good operation, low labor intensity.

6. Operation in heat and cold conditions, no additiional heating or cooling system required, easy operation.

7. Independent fluid and non-fluid agent adding system for continuous, stable and even operation.

| Type | SLG-3/300 | SLG-3/600 |

| Main unit powder(KW) | 18.5KW*3 | 37KW*3 |

| Blow powder(KW) | 5.5KW | 15KW |

| Main shaft rotating speed(RPM) | 4500 | 2700 |

| Output capacity(kg/h) | 500-1500 | 2000-4000 |

| Size(MM) | 5250*1800*5600 | 7218*3680*6450 |

Company strength

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

So far, we have established a whole production chain, the products covermicro powder grinding mill, high pressure grinding mill, European version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on. Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.

We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front. Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment,optimized process configuration and a full range of technical support, therefore we always follow your steps, pursue your value and achieve your benefit.