Products

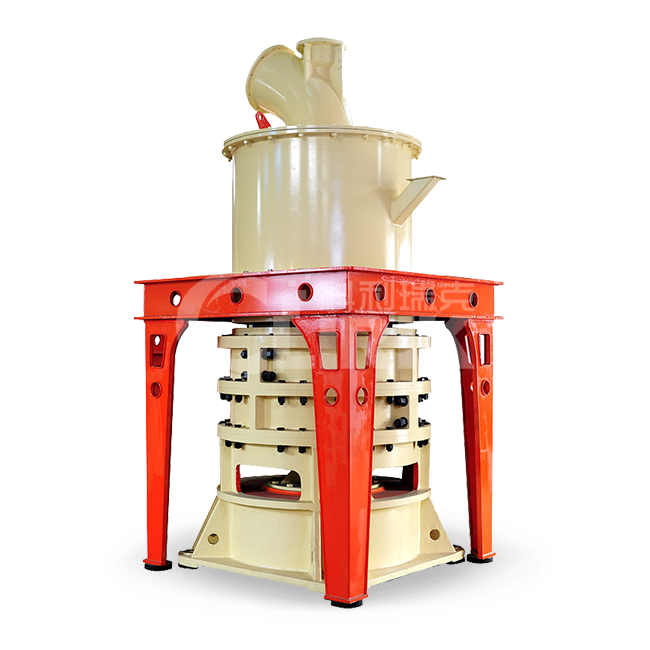

Calcite carbonate stone ultra fine mill

Calcite carbonate stone introduction:

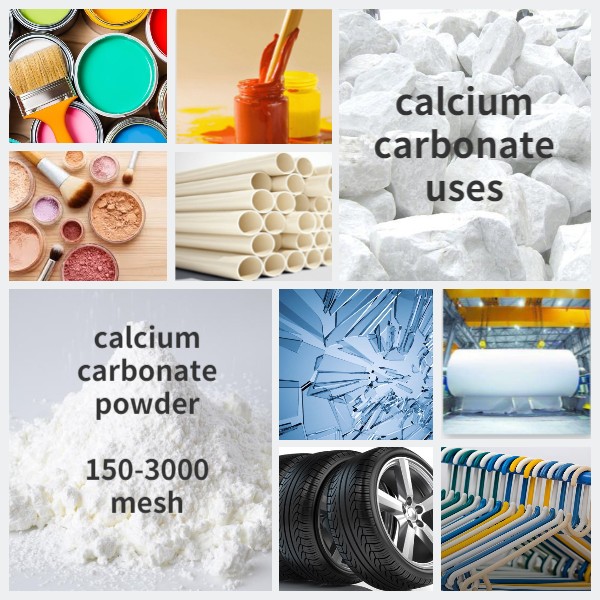

In geology and mineralogy, the term "carbonate" can refer both to carbonate minerals and carbonate rock. Carbonate minerals are extremely varied and ubiquitous in chemically precipitated sedimentary rock. The most common are calcite carbonate or calcium carbonate, calcite carbonates have been used since antiquity for cleaning and preservation, as well as for the manufacture of glass. Calcite Carbonates ore are widely used in industry, e.g. in iron smelting, as a raw material for Portland cement and lime manufacture, in the composition of ceramic glazes, and more.

Calcite carbonate ultra fine mill plant usually consists of grinding equipment main unit, classifier, powder collector, dust cleaner, induced draft fan, muffler, sound-proof room, crusher machines, bucket elevator, storage hopper, and vibrating feeder.

>>Introduce of Calcite carbonate ultra fine mill:

Calcite carbonate ultra fine mill can be used in pulverizing non-inflammable, non-explosive and brittle materials with Moh’s hardness under nine, such as calcite, kaolin, limestone, calcite, barites, carbon black, mica, quartz etc. With the development of high-tech industry, fine and superfine powder is widely applied in various fields, Clirik Calcite carbonate ultra fine mill become more and more requires by various industries.

>>Working principle of Calcite carbonate ultra fine mill:

Clirik Calcite carbonate ultra fine mill working principle is when the Calcite carbonate ultra fine mill is at work, all the grinding rollers are rolling in the ring, and the materials are driven to the edge of the turnplate by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed, crushed and grinded by the rollers.

After crushed by hammer crusher, the large materials become small ones and are sent to storage hopper by elevator, edge of then evenly sent to the upper distribution plate of the turnplate by vibrating feeder and sloping feeding pipe. The high-pressure air blower constantly inhales air within the grinding mill and, in turn, the air flow with crushed materials are brought to the classifier whose high-speed impeller will screen the airflow: the unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector. Most of the qualified powders will fall an exit from the discharging valve at the bottom; a small proportion of the fine powders, with airflow, moves to the dust cleaner, and clings to the surface of the filter bags.

At the same time, the fine powders clinging to the surface fall down by the sudden vibration of the filter bags, which is caused by the instantly ejected high-pressure gas controlled by the pulse valve. The materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed. In addition, filtered clean air will be emitted from the air outlet of muffler in the end.

>>Features of Calcite carbonate ultra fine mill:

***High efficiency

Under the same finished final size and the same motor power, the capacity of micro powder grinding mill is twice as much as jet mill, mixing grinder and ball mill.

***Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 2-3times longer than impact mill or turbo mill. Furthermore, the lifetime can reach 2-5 years for grinding calcite carbonate.

***High safety and reliability

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

***High fineness and flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 3000 meshes, and the product fineness can reach D97≤5um.

***Environment-friendly

The application of pulse deduster and muffler greatly alleviates dust pollution and noise.

Technical data of Calcite carbonate ultra fine mill:

| Parameters of HGM series ultrafine mill | |||||||

|---|---|---|---|---|---|---|---|

| Model | HGM80 | HGM80A | HGM90L | HGM100L-Ⅱ | HGM100P | HGM125L | HGM1680L |

| Ring Diameter(mm) | 800 | 800 | 900 | 1000 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3 | 4 | 4 | 4 | 4 | 4 |

| Input Size (mm) | ≤10 | ≤10 | ≤10 | ≤15 | ≤15 | ≤20 | ≤20 |

| Adjustable range of finished product (mesh) | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 | 150-3000 |

| Capacity (t/h) | 0.5-5.5 | 0.5-5.5 | 0.8-6.5 | 1.2-10 | 1.2-11 | 2.5-20 | 5-45 |

| Outlet Size L*W*H (mm) | 8605*4139*6050 | 10454*3393*6626 | 11735*3952*7525 | 14507*3633*7562 | 14362*4200*7562 | 19261*4406*8591 | 25067*5414*9007 |

| Main motor power (kw) | 75 | 75 | 55*2 | 132/75*2 | 132/75*2 | 185 | 315 |

Company strength

SHANGHAI CLIRIK MACHINERY CO., LTD located in PUDONG New district of Shanghai china as a pioneer enterprise, which is specializing in research, manufacture and sales of all kinds of mining equipment. Our company has already formed a full set of modern production line, equipped with intelligent, standardized testing and controlling laboratories, owned a professional team for R&D, production, sales and service.

So far, we have established a whole production chain, the products covermicro powder grinding mill, high pressure grinding mill, European version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and so on. They are widely used in the industry of mining, construction materials, chemicals, metallurgy, transportation, hydraulic engineering and so on. Specially we independently developed HGM micro powder grinding mill, which are not only renowned in domestic market, but also have been sold widely in Eastern Europe, Middle East, Africa, South Asia, Southeast Asia, Oceania, and America, etc.

We still insist on the communication and cooperation with prestigious scientific research institutions from both home and abroad to make our development ability always is in the domestic front. Based on the principle of constant innovation and quality guarantee, customer foremost, we are able to provide our customers not only the highest quality products at the most favorable price but also the most reasonable solution, such as the selection of the equipment,optimized process configuration and a full range of technical support, therefore we always follow your steps, pursue your value and achieve your benefit.