The ultra-fine calcium carbonate processing plant in our company not only remains good reputation in the calcium carbonate powder fineness processing, but also be popular for its auxiliary equipment. Powder surface coating machine is one of the auxiliary machines in the whole ultra-fine stone (calcium carbonate) processing plant. The powder surface coating machine with unique chamber design is applicable to the modification of many materials. Of course, calcium carbonate powder is definitely included here.

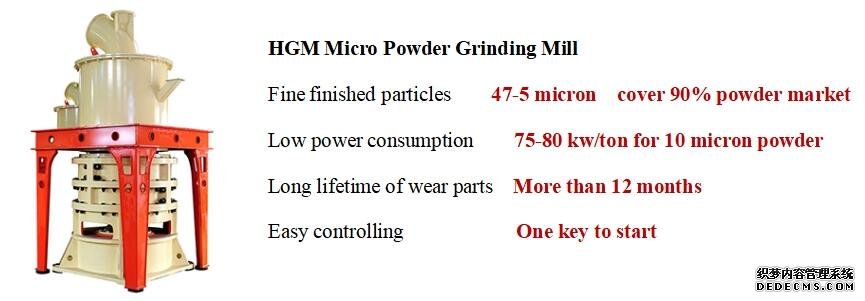

So it’s necessary to choose one good quality ultra fine powder mill for calcium carbonate powder grinding. The advantages of calcium carbonate ultra fine powder mill as follow:

1.High Efficiency.

Under the same finished final size and the same motor power, the capacity of the machine is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

2.Long life cycle of spare parts.

The ring and roller are forged by special material with high utilization,the lifetime can reach 2-5 years for grinding calcite carbonate.

3.High safety and reliability.

As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

4.High fineness, flexible adjustment.

The final fineness of the grinding materials can be adjusted between 325 meshes and 2500 mesh (47-5 micron), and the product fineness can reach D97≤5μm.

5.Environment-friendly.